Nearly a tenth of local manufacturers have seen capacity utilisation reaching 100% on the back of import restrictions by government, a new report on the state of the manufacturing sector has shown.

BY TATIRA ZWINOIRA

Import restrictions came as a result of ballooning imports with the bill at $2,5 billion in the six months to June.

The restrictions were also aimed at protecting local industries that, although showing promises, were choked by competition from imports.

Government responded with protective measures such as Statutory Instruments (SI) 6 and 126 of 2014, SI 18, 19, 20 and SI 64 of 2016, which restricted the importation of 43 products.

According to the Manufacturing Sector Survey 2016 report, 7% of the companies reported full capacities.

The report is produced annually by the Confederation of Zimbabwe Industries (CZI) to check the pulse of the manufacturing sector.

Chloride Zimbabwe, a unit of Zimbabwe Stock Exchange-listed Art Corporation, is one such company with capacity utilisation at 100%.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

- Councils defy govt fire tender directive

Keep Reading

The company benefitted from SI 20 of 2016 that restricted the importation of batteries.

Before the restrictions, Chloride Zimbabwe was operating at 64% capacity utilisation and was supplying 15 000 batteries per month into the market.

It was only after SI 20 of 2016 was gazetted that regulated imported batteries that the company’s fortunes began to turn.

“It took three months to get to full capacity. We are now supplying 20 000 batteries into the market and exporting to Zambia, Malawi and the Democratic Republic of Congo,” Art Corporation group CEO Tapiwa Ameer said.

As a result of increased capacity, Art Corporation invested $3 million into new battery making machinery, which was commissioned two months ago.

“The increased capacity has enabled Chloride Zimbabwe to reduce cost of production and increased economies of scale. This will result in a wider range of batteries, better quality and will enable the factory to catch up with the rest of the world in technology,” Ameer said.

“Apart from ensuring employment, this has also helped the country in reducing imports and increasing exports, thereby generating the much-needed foreign currency.”

Government has promulgated a number of regulations to protect local industries. SI 6 of 2014 regulated imported sugar, poultry and pork.

SI 126 of 2014 restricts the importation of liquid or powdered milk, potatoes, tomatoes, onions, biscuits, yeast, cement, soap and soap preparations, plastic bags of polymers, tubes, pipes, conveyor belts and rubber hoses.

SI 18 of 2016 listed several pharmaceutical medicines while SI 19 of 2016 listed second-hand clothing, shoes, and blankets. SI 20 of 2016 listed specific kinds of batteries, candles, floor polish and tobacco twine. SI 64 of 2016 restricted the importation of 43 products that include yoghurts, flavoured milks and dairy juice blends, among others.

Other companies that enjoyed increments include Schweppes who benefitted from SI 64 of 2016, which restricted the importation of bottled water.

Dairibord also increased capacity due to the import limitation of coffee creamers, peanut butter, powdered milk, maheu, dairy juice blends, ice-creams and cultured milk and cheese. As result, the dairy company has managed to slightly grow its market share.

Dairibord Holdings chief executive officer Anthony Mandiwanza did not answer repeated calls from Standardbusiness on Friday.

However, CZI president Busisa Moyo said despite the growth in capacity utilisation, liquidity challenges threatened to undermine further growth of the sector.

He said the central bank has to efficiently allocate the foreign currency for foreign payments on imported raw materials.

Currently, 68% of raw materials needed in the manufacturing sector are imported.

Manufacturers have of late experienced delays in making foreign payments to suppliers on the back of the central bank struggling to allocate foreign currency to different sectors.

“With the current liquidity challenges, we could see those results undermined; that is, liquidity to support those companies. Foreign currency allocation will be critical to support those companies so that they are nurtured. When the liquidity problems go away, we still have a manufacturing sector that is growing and strong,” Moyo said.

“I think we need to look at a sector by sector approach. I think we need to look at food, clothing, and furniture sectors as low-hanging fruits where we can look at how we can further spur growth in those sectors and grow. We can also look at companies that were excluded from SI 64 of 2016 [companies still affected by imports] and look at how we can get them on as well.”

Government has been calling on manufacturers to export to avoid putting constrains on foreign exchange needed in the country.

For example, Oil Expresser’s Association of Zimbabwe has a capacity to fully supply the market, leaving an additional two million litres. It has not exported the excess output.

The importation of crude oil for cooking oil consumes a huge chunk of foreign exchange, second only to fuel. Overall capacity utilisation as a result of import restrictions has grown by 13,1 percentage points to 47,4%.

Despite the growth, companies that relied on imported products have been affected by the restriction of imports. They have been advised to collate their grievances as a sector for consideration by the ministry of Industry and Commerce.

The grievances would be collected and signed on as memorandum of understanding, presented to the association responsible and taken to CZI, which, in turn, would take it to the ministry.

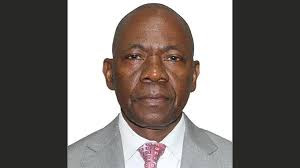

Industry and Commerce minister Mike Bimha said the growth of capacity utilisation by 13,1 percentage points was a step in the right direction, imploring industry not to be complacent as the restrictions were temporary.

“What we are going to do is where companies require funding, we will support them to retool and re-equip with newer technologies to remain updated and efficient. When we remove them [import restrictions], companies will have to stand on their own and they can only do that if they up their game with newer technologies,” Bimha said.

He said the National Competitiveness Bill was sitting with cabinet, which would look at cost structures to help manufacturers produce at lower costs.

“We need to plug holes in corruption where some companies are smuggling goods. And we are discussing some of these issues at an inter-ministerial level which is chaired by the Home Affairs ministry,” he said.