It is generally agreed that approximately two thirds of every dollar of every business revenue stream finds its way through the back door of procurement. Because of that, the traditional role of procurement has come under serious scrutiny of late. This makes a compelling argument for procurement professionals to realise that its role has been progressively changing over the past two decades or so. Procurement practitioners have over the years advocated that there is now need (more than ever) to place the procurement function in line with the strategic goals of the business. It is now time for the procurement practitioners to ensure that they always have a broad general business understanding and a full grasp of the company’s overall business strategy so as to maximise on procurement strategies that are specifically tailor made to reflect the organisation’s strategic value proposition. Procurement departments can only have their place on the executive table if, and only if, the mindset of the department changes from a reactive server approach to a more proactive business partner concerned with offering ultimate value to both the top line and the bottom-line.

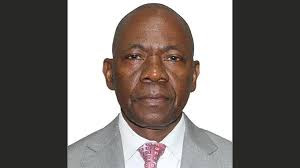

supply chain with CHARLES LOVEMORE NYIKA

While procurement’s traditional role as a cost killer is no secret, smart procurement business leaders ordinarily are renowned for going beyond the narrow focus of cost reduction. Today’s procurement professionals are no longer price watchers but are now regarded as business builders who should see and craft opportunities that add value progressively. Except wages, everything goes through the hands of procurement and this makes a compelling argument for the profession to realise its changed status and what it can do to influence the profit and loss account. Over time, procurement savings will continue to dwindle and where the procurement practitioners continue to push suppliers for perennial price reductions, this will inevitably lead to supplier relationships straining to a breaking point.

Getting past the low-hanging fruit of cost reduction requires new business thought processes. Instead of pushing so hard to squeeze out that additional price reduction from the poor supplier, which may inevitably damage the supplier’s profitability in the process, it may be advisable to focus on other issues such as price analysis or process costs analysis in collaboration with suppliers. Reducing process costs involve understanding which processes are bureaucratic and redundant and should be targeted for elimination by your suppliers and or your organisation. Procurement professionals should be able to assist their organisations by identifying processes which are simpler, faster and better as a way of saving costs.

The maximum potential reach of the procurement department can only be achieved where the department serves as a customer centric department since the process of manufacturing goods for consumers begins with the source of appropriate raw materials. The sourcing of raw materials that are sub-standard will obviously result in product outcomes that are equally sub-standard. As is always the norm, sub-standard products are very costly to the business and can ruin the reputation of any business, even where there is a proven previous track record of quality. As is often said, whenever an organisation allow, rework to be done, the work is being done twice while the organisation is paid once. Procurement should therefore realise that whatever decisions they make at the beginning of the supply chain process can have serious repercussions to the business, particularly at the consumer end of the supply chain.

The scope of the procurement office can be as efficient and as effective as the procurement practitioner makes it. Today’s best-in-class procurement professionals are slowly realising that in-order to transform the procurement function into a value add department, there is need to recognise that the days of “price-street fighting” with suppliers are now behind us. What is now required is a paradigm shift where procurement is expected to add value to the business by forming collaborative relationships with the supply community. By harnessing the core competencies of suppliers, best-performing procurement practitioners are now relying heavily on utilising the unique technologies and expertise of suppliers to come up with highly innovative products and cost reduction manufacturing methods and processes. The new language of success in today’s business world recognises that supplier collaboration relationships happen to be the iron law of innovation development whether at product level or at process level.

The time has also come for supply chain professionals to move out of the commercial shadows and take a pivotal role in bringing value to the corporate table by making use of data based instruments on the procurement radar screen or dashboard “to monitor market indices and significant effects on significant events”. This will enable them to gain a fairly predictive edge on the supply chain market and enable them to “explain the unexplainable”. Procurement professionals are now required to have “a vast network of eyes, ears and antennas” on the supply market as a way of mitigating supply chain risks in this highly volatile business environment. Industry observers have pointed that “supply managers should use fog lamps and night-vision goggles to just make sense of things and get some early warning signs of potential risks in the supply market”. Supply chain risk management is now a strategic imperative and procurement should ensure that the organisation is sheltered from any potential risks, imagined or real.

There is need to initiate, develop and consolidate long-lasting mutually beneficial relationships with strategic suppliers as a way of narrowing the gap between suppliers and the buyer’s supply needs. Regular contacts with suppliers (even where you do not require anything from the supplier) can assist in the removal of redundant efforts and the identification and correction of sources and symptoms of quality problems. Procurement practitioners should therefore map a supply chain and try to understand the flow of raw materials from one organisation to the other. This will easily identify areas of eliminating waste and those areas that requires process improvements. Bottom line savings achieved through strong supplier collaboration strategies have significantly resulted in demonstrable spend reductions which result in direct positive impact on the profit and loss account. One dollar saved through procurement is one dollar earned without any cost of sale.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

- Councils defy govt fire tender directive

Keep Reading

Charles Lovemore Nyika is a supply chain practitioner based in Harare. For views and comments, he can be contacted at [email protected]